Revolutionize. Optimize. Lead.

Get in TouchTransforming Industries with Advanced Digital Twin Solutions

Transforming Industries with Advanced Digital Twin Solutions

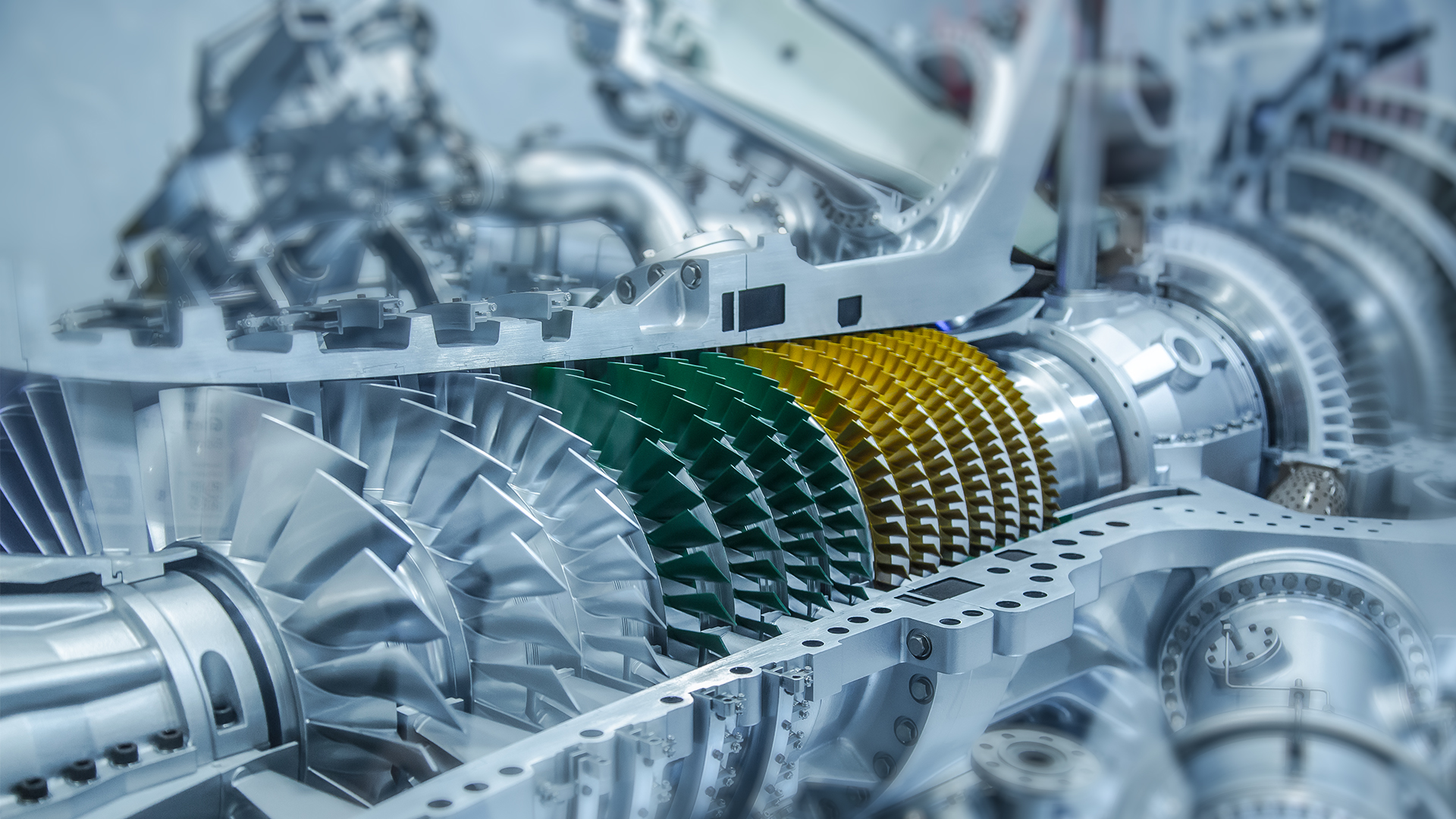

In an industrial world driven by relentless innovation, Digital Twins are not just a buzzword—they are the foundation of the next industrial revolution.

At KiXR, we deliver cutting-edge Digital Twin services designed to redefine operational efficiency, unleash hidden potential, and create a future-ready enterprise.

Our tailored Digital Twin services empower industries with highly immersive 3D, seamless integration with IoT, delivering actionable workflows in training, safety, simulation, analytics.

Our specialization includes creating Digital Twins in Manufacturing, Shipping and Logistics, Defence, Automotive and Aerospace.

What Are Industrial Digital Twins?

Digital Twins are virtual replicas of physical assets, processes, or systems. By combining real-time data using IoT, machine learning, and 3D and simulation technologies, they enable businesses to:

- Monitor operations in real-time.

- Predict maintenance needs and prevent downtime.

- Training and Safety

- Enhance product lifecycle management.

- Optimize resource allocation and energy usage.

Our Digital Twin Services

Our Digital Twin Services

We don’t believe in one-size-fits-all. Every solution is engineered to meet your unique operational needs:

• Single-Asset Twins: Deep dive into critical equipment performance.

• Integrated System Twins: Visualize and optimize your entire ecosystem.

Data is powerful—but only when it’s actionable. Our solutions blend data streams from IoT devices, sensors, and cloud platforms into a single source of truth, empowering:

• Live Monitoring: React faster, smarter, better.

• 360° Dashboards: See what matters most—instantly.

Why react when you can anticipate? With AI and machine learning at the core, our Digital Twin services help you:

• Eliminate Downtime: Predict failures before they happen.

• Cut Maintenance Costs: Focus only where attention is needed.

Stop guessing and start simulating. Our process optimization services identify inefficiencies, model improvements, and deliver solutions that work in the real world.

• Dynamic Workflow Analysis: Adapt to change effortlessly.

• Energy Optimization: Minimize costs while maximizing sustainability.

Train teams smarter, faster, and safer. With Digital Twin-powered simulations, your workforce can master real-world scenarios without the risks:

• Virtual Simulations: Test critical operations in a risk-free environment.

• Skill-Boosting Modules: Empower operators with precision tools.

Industries We Serve

We provide Industrial Digital Twin solutions across diverse sectors, including:

- Manufacturing: Improve factory operations and ensure seamless production..

- Energy and Utilities: Optimize power generation and distribution networks.

- Oil and Gas: Enhance asset management and pipeline monitoring.

- Transportation: Streamline logistics, fleet management, and infrastructure planning.

- Automotive and Aerospace: Safety, training and simulation

Why KiXR?

Why KiXR?

We bring the latest in 3D, GenAI, Computer Vision, IoT, and data science to power solutions that make a difference.

Every Digital Twin we create is customized, precise, and designed with your success in mind.

From cost savings to productivity boosts, our clients see measurable, sustained benefits.

Ready to unlock the next level of industrial intelligence? At KiXR, we deliver more than technology—we deliver results.

FAQ

A digital twin is a virtual representation of a physical object or system that enables real-time monitoring, analysis, and simulation of its behavior and performance.

While simulation models a system's behavior under specific conditions, a digital twin is an exact virtual replica of a physical object or system, offering real-time data and insights into its actual performance.

The three main types of digital twins are: - Product digital twins, representing individual physical products. - Process digital twins, modeling and simulating entire processes or systems. - System digital twins, representing larger-scale systems or ecosystems.

Digital twins are essential as they provide real-time insights into the performance of physical objects or systems, facilitating better decision-making, predictive maintenance, and operational optimization.

The benefits of digital twins include: - Improved operational efficiency - Predictive maintenance - Reduced downtime - Enhanced decision-making - Better product and process optimization - Cost savings

KiXR offers digital twin solutions tailored to various industries, including: - Supply Chain: Real-time monitoring, optimization, and predictive analytics. - Construction: Virtual modeling, progress tracking, and resource optimization. - Manufacturing: Real-time monitoring, analysis, and predictive maintenance. - Retail: Insights into customer behavior, store layouts, and inventory management.